Requirements for the installation and operation of the steering rack.

Explanations on the replacement of oil seals.

Requirements for the installation and operation of the steering rack.

Before replacing the steering rack, it is required:

- If there is an on-board stabilization system on the vehicle, disconnect the battery from the on-board network

- Run the rinse of the power-assisted system. Make sure of the serviceability of the following:

-the other components of the hydraulic system

-the front suspension parts

-the gimbal (s)

-steering rods, steering tips, anthers, and clamps

Installation requirements:

- Works must be carried out strictly in accordance with the requirements of the car manufacturer’s factory.

- Work must be carried out by qualified personnel.

- During the installation, do not allow mechanical impact on the unit (impacts on the steering cardan or steering rack)

After installing the steering rack, it is required:

- Remove air from the hydraulic system based on the recommendation

- Adjust the angle of convergence of the steered wheels

- Connect the servotronic connector (if any) or any other sensors on the steering rack (if equipped)

- Calibrate the rudder position sensor (if available)

- Adapt the steering rack (if the rail is electric)

- Check the hydraulic system for leaks

Recommendations for removing air from the power steering system

- Raise the front of the car until the wheels break off the surface of the platform and install the vehicle on the supports.

- Fill the hydraulic fluid in the expansion tank to the maximum mark

- Start the engine and immediately stop it

- Wait 10 minutes (to remove air from the hydraulic system)

- Add hydraulic fluid to the expansion tank to the maximum mark

- Create a voltage on the steering wheel (without rotation) to the left and start the engine for 5 seconds.

- Wait 5 minutes (to remove air from the hydraulic system)

- Add hydraulic fluid to the expansion tank to the maximum mark

- Start the engine and slowly turn the steering wheel Left, then right until it stops. If there is noise during the operation, grind – stop the motor and go to step 6.

- Check and adjust the level of the liquid in the expansion tank and, if necessary, add hydraulic fluid

- After replacing the steering rack, on the first day of operation it is advisable not to exceed the engine speed more than 4000 rpm.

Explanations on the replacement of oil seals.

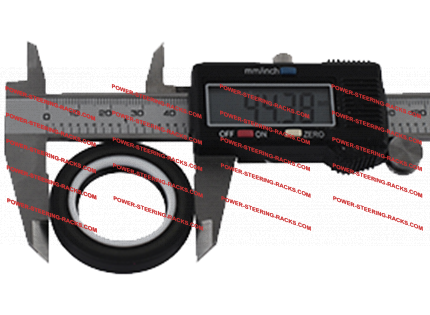

If you do not know the oil seal number or its dimensions, you will have to remove the oil seal from the steering rack or power steering pump. While measuring the caliper, it should be taken into account that it may be slightly different from the values given on the oil seal itself or in the description on the site. As a rule, some values are rounded. For example, an oil seal F-01023 has a size 28 * 44 * 7.2 (7V2) in the description and on the case. In real measurement, we see the following picture:

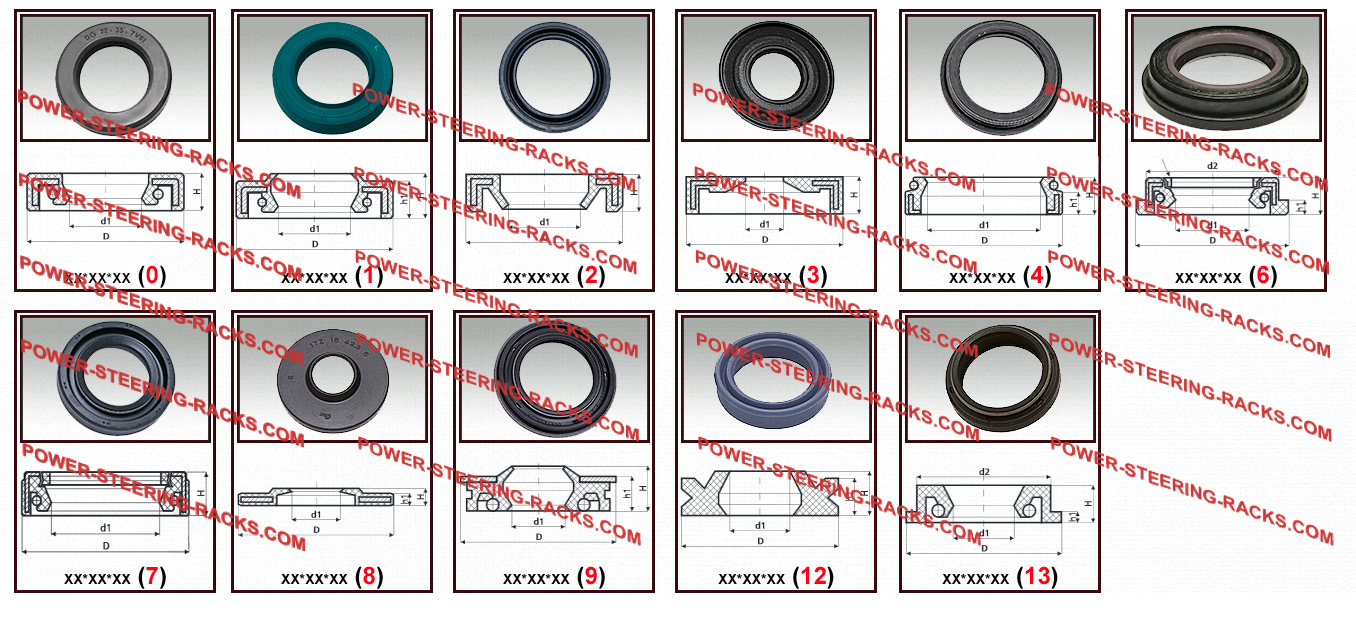

When measuring, it should also be taken into account that the extracted packing, has a certain degree of wear and its size from the new one will be different. When selecting the oil seals, it should be borne in mind that the oil seals have 11 basic types in shape. The shape of the oil seal is indicated along with the dimensions, the value in brackets corresponds to the type

German

German Spanish

Spanish French

French